Ho Welding ke Eng?

The tjheseletsa bokgoni ba tšepe e bua ka ho ikamahanya le maemo a lintho tse bonahalang tse tšepe tshebetso tjheseletsa, haholo-holo e bua ka bothata ba ho fumana boleng bo phahameng manonyeletso welded tlas'a maemo a itseng tjheseletsa tshebetso.Ha re bua ka mokhoa o pharaletseng, khopolo ea "bokhoni ba weld" e boetse e kenyelletsa "boteng" le "ts'epehi".Bokhoni ba weld bo itšetlehile ka litšobotsi tsa thepa le maemo a ts'ebetso a sebelisoang.Bokhoni ba weld ea thepa ea tšepe ha e tsitsitse empa e tsoela pele ho etsa mohlala, bakeng sa lisebelisoa tseo qalong li neng li nkoa e le tse futsanehileng ka bokhoni ba weld, ka tsoelo-pele ea saense le theknoloji, mekhoa e mecha ea ho tjheseletsa e se e le bonolo ho tjheseletsa, ke hore, bokhoni ba tjheseletsa. e se e le betere.Ka hona, re ke ke ra tlohela maemo a ts'ebetso ho bua ka bokhoni ba weld.

Bokhoni ba weld bo kenyelletsa likarolo tse peli: e 'ngoe ke ts'ebetso e kopaneng, ke hore, maikutlo a ho theha mefokolo ea welding tlasa maemo a itseng a ts'ebetso ea welding;ea bobeli ke ts'ebetso e sebetsang, ke hore, ho ikamahanya le maemo ha lenonyeletso le cheselitsoeng ho latela litlhoko tsa tšebeliso tlasa maemo a itseng a ts'ebetso ea welding.

Mekhoa ea ho Welding

1.Laser welding(LBW)

2.ultrasonic welding (USW)

3. diffusion welding(DFW)

4. joalo-joalo

1.Welding ke mokhoa oa ho kopanya lisebelisoa, hangata litšepe, ka ho futhumatsa libaka ho fihlela ho qhibiliha ebe o li lumella hore li pholile le ho tiisa, hangata ka ho eketsoa ha thepa ea ho tlatsa.The weldability ea thepa e bolela bokhoni ba eona ba ho tjheseletsa tlas'a maemo a itseng a tshebetso, 'me ho itšetlehile ka litšobotsi tsa thepa le mokhoa oa ho cheselletsa o sebelisoang.

2.Weldability e ka aroloa ka likarolo tse peli: ts'ebetso e kopanetsoeng le ts'ebetso e sebetsang.Ts'ebetso e kopaneng e bua ka kutloelo-bohloko ea ho theha mefokolo ea welding tlasa maemo a itseng a ts'ebetso ea welding, ha ts'ebetso e sebetsang e bua ka ho ikamahanya le maemo ha lenonyeletso le ts'oereng litlhoko tsa ts'ebeliso tlasa maemo a itseng a ts'ebetso ea welding.

3.Ho na le mekhoa e sa tšoaneng ea ho cheselletsa, ho akarelletsa le laser welding (LBW), ultrasonic welding (USW), le diffusion welding (DFW), har'a tse ling.Khetho ea mokhoa oa ho tjheseletsa o ipapisitse le lisebelisoa tse kopantsoeng, botenya ba lisebelisoa, matla a kopantsoeng a hlokahalang, le lintlha tse ling.

Ho Welding ka Laser ke Eng?

Laser welding, eo hape e tsejoang e le laser beam welding ("LBW"), ke mokhoa oa ho etsa moo likotoana tse peli kapa ho feta tsa thepa (hangata litšepe) li kopanngoang ka tšebeliso ea lebone la laser.

Ke ts'ebetso e sa amaneng le batho e hlokang ho fihlella sebaka sa weld ho tloha lehlakoreng le leng la likarolo tse cheselitsoeng.

Mocheso o entsoeng ke laser o qhibilihisa thepa e mahlakoreng ka bobeli a lenonyeletso, 'me ha thepa e qhibilihisitsoeng e tsoakana le ho tiisa, e kopanya likarolo.

The weld e thehoa ha lebone le matla la laser le futhumatsa thepa ka potlako - hangata e baloa ka milliseconds.

Leqhubu la laser ke leseli le momahaneng (mohato o le mong) oa leqhubu le le leng (monochromatic).Lebone la laser le na le phapano e tlase ea maballo le matla a mangata a tla baka mocheso ha o otla bokaholimo

Joalo ka mefuta eohle ea ho cheselletsa, lintlha li bohlokoa ha u sebelisa LBW.U ka sebelisa li-laser tse fapaneng le lits'ebetso tse fapaneng tsa LBW, 'me ho na le linako tseo ka tsona welding ea laser e seng khetho e ntle ka ho fetisisa.

Laser Welding

Ho na le mefuta e 3 ea laser welding:

1.Mokhoa oa ho tsamaisa

2.Mokhoa oa ho tsamaisa/ho kena

3.Ho kena kapa mokhoa oa ho kenya senotlolo

Mefuta ena ea laser welding e arotsoe ka bongata ba matla a fanoang ka tšepe.Nahana ka tsena e le matla a tlase, a mahareng, le a phahameng a matla a laser.

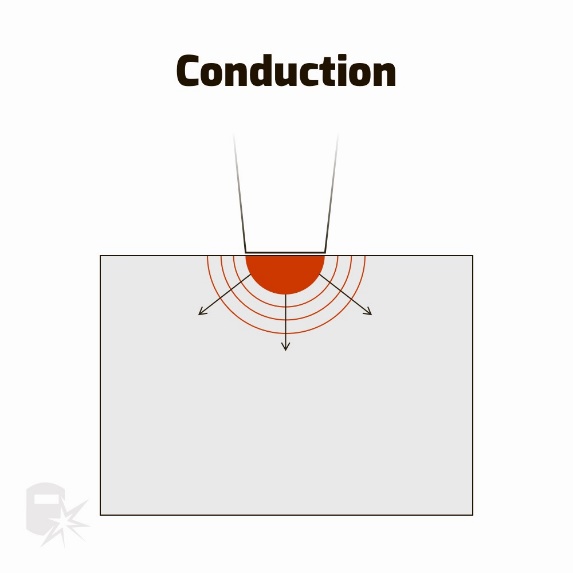

Mokhoa oa ho tsamaisa

Mokhoa oa ho tsamaisa o fana ka matla a laser a tlase ho tšepe, e bakang ho kenella ho tlase ka chese e sa tebang.

E ntle bakeng sa manonyeletso a sa hlokeng matla a phahameng kaha liphetho ke mofuta o tsoelang pele oa weld.Li-welds tsa conduction li boreleli ebile lia khahleha, 'me hangata li pharalletse ho feta kamoo li tebileng.

Ho na le mefuta e 'meli ea mokhoa oa conduction LBW:

1.Ho futhumatsa ka ho toba:Karolo e ka holimo ea karolo e futhumatsoa ka ho toba ka laser.Joale mocheso o etsoa ka har'a tšepe, 'me likaroloana tsa tšepe ea motheo lia qhibiliha, li kopanya motsoako ha tšepe e tsosolosa.

2.Phetiso ea Matla: Enke e khethehileng e monyang e qala ka ho behoa sebopehong sa manonyeletso.Enke ena e nka matla a laser 'me e hlahisa mocheso.Joale tšepe e ka tlas'a eona e tsamaisa mocheso hore e be lesela le lesesaane, le qhibilihe, le be le tiile ho etsa lenonyeletso le cheselitsoeng.

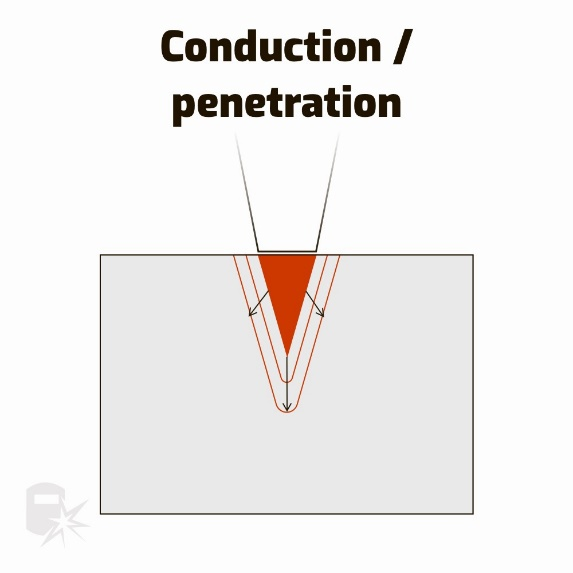

Tsamaiso/Mokgwa wa ho Kena

Ba bang ba kanna ba se ke ba amohela sena e le o mong oa mekhoa.Ba ikutloa hore ho na le mefuta e 'meli feela;o ka tsamaisa mocheso ka har'a tšepe kapa o etsa mouoane mocha o monyenyane oa tšepe, o lumella laser hore e theohele ka har'a tšepe.

Empa mokhoa oa conduction / ho kenella o sebelisa matla a "bohareng" mme o fella ka ho kenella ho hoholo.Empa laser ha e na matla a lekaneng ho etsa mouoane oa tšepe joalo ka ka har'a keyhole mode.

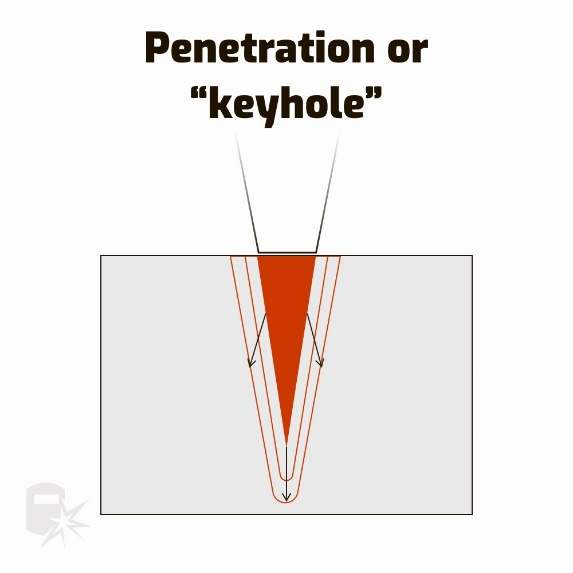

Ho kenella kapa Mokhoa oa Keyhole

Mokhoa ona o etsa li-welds tse tebileng, tse moqotetsane.Kahoo, ba bang ba e bitsa mokhoa oa ho kenella.Li-welds tse entsoeng hangata li tebile ho feta bophara le matla ho feta li-welds tsa conduction mode.

Ka mofuta ona oa tjheseletsa ea LBW, laser e matla haholo e etsa mouoane tšepe ea motheo, e etsa kotopo e moqotetsane e tsejoang e le "mokokotlo oa senotlolo" o theohelang lenonyeletsong."Lesoba" lena le fana ka kotopo ea hore laser e kene ka hare ho tšepe.

Litšepe Tse Loketseng Bakeng sa LBW

Laser welding e sebetsa ka litšepe tse ngata, joalo ka:

- Tšepe ea Carbon

- Aluminium

- Titanium

- Alloy e tlaase le tšepe e sa hloekang

- Nickel

- Platinum

- Molybdenum

Ultrasonic welding

Ultrasonic welding (USW) ke ho kopanya kapa ho fetola thermoplastics ka tšebeliso ea mocheso o hlahisoang ke motsamao o phahameng oa maqhubu.E finyelloa ka ho fetola matla a motlakase a maqhubu a phahameng hore e be motsamao o phahameng oa maqhubu.Ho sisinyeha hoo ha mochini, hammoho le matla a sebelisoang, ho baka mocheso o sa tsitsang sebakeng sa ho nyalana sa likarolo tsa polasetiki (sebaka se kopaneng) kahoo thepa ea polasetiki e qhibiliha ebe e theha maqhama a molek'hule lipakeng tsa likarolo.

MOLAO-MOTHEO OA ULTRASONIC WELDING

1.Parts in Fixture: Likarolo tse peli tsa thermoplastic tse tla kopanngoa li behiloe hammoho, e 'ngoe ka holim'a e' ngoe, sehlaheng se tšehetsang se bitsoang fixture.

2.Ultrasonic Horn Contact: Karolo ea titanium kapa aluminium e bitsoang lenaka e tlisoa ka karolo e ka holimo ea polasetiki.

3.Force e sebelisitsoeng: Matla a laoloang kapa khatello e sebelisoa likarolong, ho li kopanya hammoho khahlanong le sebopeho.

4.Weld Nako: Lenaka la ultrasonic le sisinyeha ka ho otloloha ka makhetlo a 20,000 (20 kHz) kapa 40,000 (40 kHz) ka motsotsoana, boholeng bo lekantsoeng ka likete tsa inch (microns), bakeng sa nako e reriloeng esale pele e bitsoang nako ea weld.Ka moralo o hlokolosi oa karolo, matla ana a thothomelang a lebisitsoe libakeng tse lekanyelitsoeng tsa ho kopana lipakeng tsa likarolo tse peli.Li-vibrations tsa mochini li fetisoa ka thepa ea thermoplastic ho ea ho sehokelo se kopaneng ho theha mocheso o tsitsitseng.Ha mocheso oa motsoako o kopanetsoeng o fihla sebakeng sa ho qhibiliha, polasetiki e qhibiliha ebe e phalla, 'me ho thothomela ho emisoa.Sena se lumella polasetiki e qhibilihisitsoeng hore e qale ho pholile.

5.Hold Time: The clamping force e bolokoa ka nako e reriloeng esale pele ho lumella likarolo ho kopanya ha polasetiki e qhibilihisitsoeng e pholile le ho tiisa.Sena se tsejoa e le nako ea ho ts'oara.(Tlhokomeliso: Matla a ntlafetseng a manonyeletso le hermeticity e ka finyelloa ka ho sebelisa matla a phahameng nakong ea ho tšoara nako. Sena se finyelloa ka ho sebelisa khatello e habeli).

6.Horn Retracts: Hang ha polasetiki e qhibilihisitsoeng e tiisitsoe, matla a clamping a tlosoa 'me lenaka la ultrasonic le khutlisetsoa morao.Likarolo tse peli tsa polasetiki joale li kopantsoe joalokaha eka li bōpiloe hammoho 'me li ntšoa ho tloha setsing e le karolo e le' ngoe.

Diffusion Welding, DFW

Ho kopanya ts'ebetso ka mocheso le khatello moo libaka tsa ho kopana li kopantsoeng ke ho hasana ha liathomo.

Mokhoa

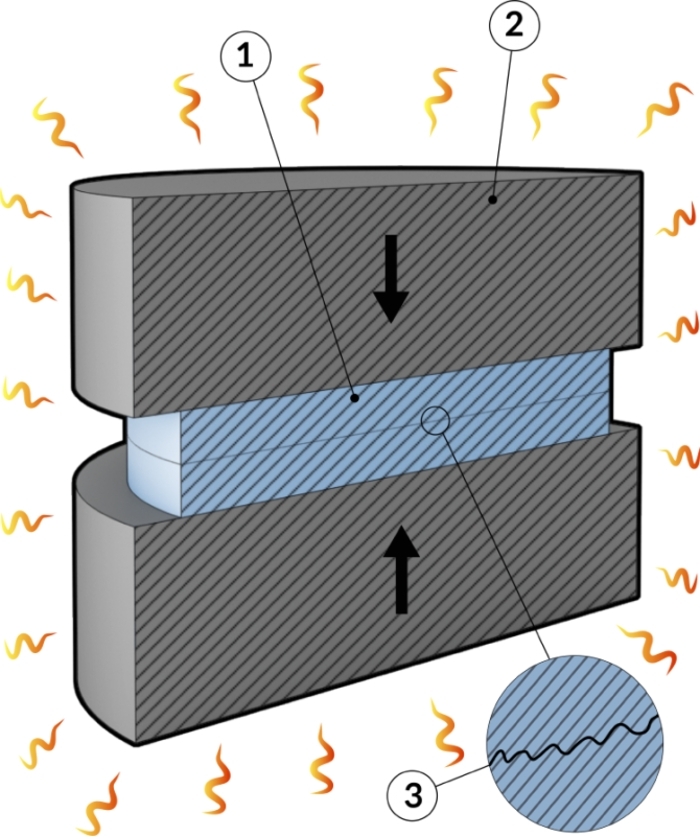

Li-workpieces tse peli [1] libakeng tse fapaneng li behoa pakeng tsa mechine e 'meli ea khatiso [2].Likhatiso li ikhethile bakeng sa motsoako o mong le o mong oa li-workpieces, ka lebaka la hore moralo o mocha oa hlokahala haeba moralo oa sehlahisoa o fetoha.

Mocheso o lekanang le hoo e ka bang 50-70% ea lisebelisoa tse qhibilihang ebe o fanoa tsamaisong, ho eketsa ho tsamaea ha liathomo tsa lisebelisoa tse peli.

Mechine e hatelloa hammoho, e leng se etsang hore liathomo li qale ho arohana pakeng tsa lisebelisoa sebakeng sa ho kopana [3].Phatlalatso e etsahala ka lebaka la hore lisebelisoa tsa mosebetsi li fapane, ha mocheso le khatello li etsa hore mokhoa ona o be bonolo.Ka hona, khatello e sebelisoa ho etsa hore lisebelisoa tse amanang le libaka li be haufi ka hohle kamoo ho ka khonehang e le hore liathomo li ka hasana habonolo.Ha karolo e lakatsehang ea liathomo e hasoa, mocheso le khatello lia tlosoa 'me ts'ebetso ea ho kopanya e phethiloe.